Biomass Dryer Suppliers & Manufacturers In India

Bagasse and its conservation has become a necessity for up coming sugar factories moving towards co-generation. Enviropol-Flash Dryers for Bagasse maximizes the generation of heat energy from the available system through substantial reduction in moisture content.

Enviropol Engineers is a leading Bagasse Dryer manufacturers, suppliers and exporters from India. We are supplying Highly Advanced Flash Dryer around the world at the most competitive prices.

Working Principle of Bagasse Dryer

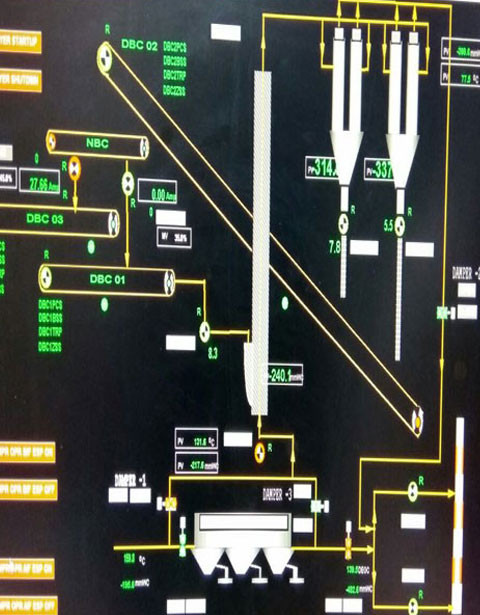

The hot and de-dusted flue gas from the boiler are made to pass through the flash tower under induced/forced draft. The wet mill bagasse is fed through rotary air lock feeder at the bottom of the tower. It is then carried upward in a co-current mode with the hot flue gas at a calculated velocity based on Average Particle Retention Time (APRT). During the process, bagasse moisture evaporates and the dried bagasse is subsequently separated through a high efficiency cyclonic separator.

The dried bagasse is continuously evecaated from the bottom of the cyclone(s) through air-lock valves for onward feeding to the boiler. The flue gar are released to the chimney through a booster ID fan. Adequate automation is provided for proper interlocking and protections.

Bagasse Dryers Enviropol Engineers PVT.LTD

Our Manufacturing Range

- Induced Draft Flash Dryer

- Forced Draft Flash Dryer

Advantages

- Bagasse Saving

- Waste Heat Recovery

- Simplified Fly Ash Management

- Enhanced Steam Generation

- Improved Boiler Efficiency

Selection Criteria

- Space availablity

- Duct Layout

- Stack Connection

- Type Of APCD

- Layout of Bagasse Conveyors

Applications

- Sugar

- Bio-Mass