Leading Biomass Dryer Manufacturers in India - Enviropol Engineers

Why Choose Enviropol for Biomass Dryer Technology?

1. Unmatched Expertise : With years of experience in the field, Enviropol Engineers possesses unparalleled expertise in designing and manufacturing biomass dryer systems. Our skilled team of engineers understands the unique requirements of the biomass & Agro Based industry and strives to deliver tailor-made solutions that meet the specific needs of our clients.

2. Cutting-edge Technology : We stay at the forefront of technological advancements in biomass drying. Our state-of-the-art manufacturing facilities are equipped with the latest machinery and equipment, enabling us to develop highly efficient and energy-saving biomass dryer systems. Our solutions provide optimal performance and maximize productivity by incorporating advanced features and automation.

3. Superior Quality : At Enviropol, we prioritize quality at every stage of the manufacturing process. Our biomass dryer systems are built using premium-grade materials and undergo rigorous quality checks to ensure durability and reliability. We guarantee long-lasting and efficient equipment that delivers consistent results by adhering to stringent quality standards.

4. Customization Options : We understand that every biomass drying application is unique. We offer flexible customization options, allowing our clients to tailor the biomass dryer systems to their specific requirements. Whether capacity, drying temperature, or moisture control, we work closely with our customers to design solutions that perfectly match their needs.

5. Excellent Customer Support : Our commitment to customer satisfaction extends beyond the manufacturing process. We provide comprehensive after-sales support, including installation, maintenance, and troubleshooting assistance. Our dedicated after sales service team is always ready to address any queries or concerns, ensuring a smooth and hassle-free experience for our valued clients.

Bagasse Dryer: Enhancing Efficiency and Sustainability in the Sugar Industry

Bagasse Drying Technology

The economic development of India with particular reference to areas such as northern states, Maharashtra, and southern states is greatly dependent on the sugar industry. The sugar manufacturing process is one of the key by-products, which is biofuel being used for the cogeneration process of bagasse. Also, the moisture content in bagasse is high and this reduces its calorific value thus the combustion of bagasse becomes less efficient, and a higher amount of fuel is required. However, the development of the Bagasse Dryer technology has been such that with it bagasse-based biomass energy generation has become a game changer in terms of efficiency. Enviropol has a vast experience of 20+ years in the Bagasse dryer installation worldwide.

Lots of bagasse is created by the sugarcane industry, a fibrous by-product of sugarcane processing. Nevertheless, raw bagasse has a moisture content of almost 50% which lowers its energy efficiency when used as fuel in cogeneration plants. The drying technology of bagasse is therefore important to enhance its calorific value by reducing the moisture content to approximately 40%. Biomass dryer systems are the carriers used where excess moisture is evaporated using hot air, flue gases, or steam. This technology enhances boiler performance and lowers harmful emissions; reduces fuel consumption by improving the combustion efficiency of bagasse; and, as a result, solves energy efficiency and environmental sustainability problems of sugar mills.

Importance of Bagasse Drying in the Sugar Industry

Over the years, this has led to the rising requirement for Bagasse Dryer Manufacturers like Enviropol which can supply economical and eco-friendly energy solutions to the sugar industry. Bagasse drying technology dries bagasse from around 50% moisture to less than 40% so that bagasse can burn more efficiently and emit less. Furthermore, this process optimizes fuel consumption and helps to decrease carbon footprints to sustain environmental consistency.

Indian leading bagasse dryer manufacturer like Enviropol is always creating new and cost-effective ways of drying technology for the sugar industry. Biomass dryer manufacturers in India supply advanced drying systems that utilize energy recovery mechanisms for fuel efficiency optimization. They significantly contribute to the reduction of operational costs and compliance with ecological regulations. Due to the rise in demand for sustainable energy solutions, sugar mills in North and Maharashtra have also found bagasse drying technology as an absolute necessity. An advanced drying technology can increase productivity, decrease carbon trails, and maximize the economic value of bagasse, transforming it from being a by-product into a product with economic value.

How Bagasse Dryer Technology Works

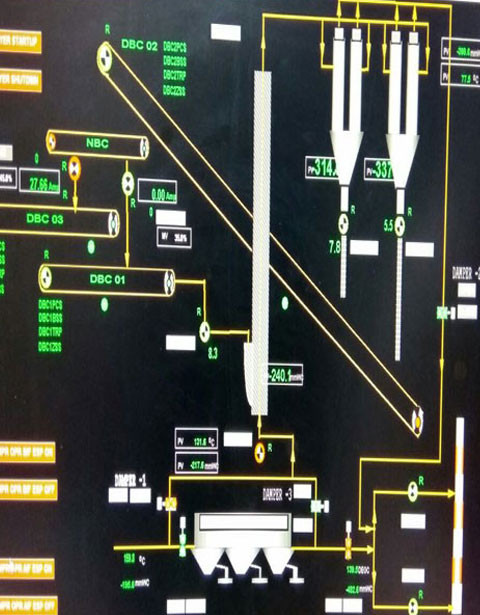

Biomass Dryer Manufacturers in India like Enviropol adopt modern designs of drying systems that extract moisture in bagasse through hot air, flue gases, or steam. The working mechanism typically involves:

1. Raw bagasse with relatively high moisture content is fed into the dryer.

2. Heat Evaporation: Heated air or gases are used to reduce moisture in bagasse.

3. Drying and Discharge: Discharge of dried bagasse into further combustion or to other use as raw material.

4. Many Biomass Dryer Systems are Energy Recovery designed such that energy is enhanced more efficiently.

Benefits of Using Bagasse Dryers in the Sugar Industry

1. Improved Calorific Value

The combustion of bagasse can be improved by reduction of moisture content, improving the calorific value so that such bagasse becomes a more efficient fuel for the boilers in sugar mills.

2. Reduced Fuel Consumption

Less extra fuel is required for the combustion of dried bagasse compared to fresh bagasse and therefore vast savings in energy costs are achieved.

3. Lower Emissions and Environmental Impact

Such combustion produces fewer harmful emissions such as carbon monoxide and particulate matter than fire normally does.

4. Increased Boiler Efficiency

Dried bagasse makes boiler operations more efficient and boosts the overall productivity of the sugar mills.

5. Versatile Applications

Dried bagasse also can be used as a biofuel as well as used in the production of paper, biocomposites, and animal feed.

This Selection of the right Bagasse Dryer Manufacturers

Things that sugar mill operators should take into account when choosing a bagasse dryer manufacturer include:

1. Reliability: The drying system should exhibit reliability and appreciate the absence of rewashing during the drying process.

2. Customization Options: According to every sugar mill each one has different requirements and when a manufacturer will have to provide them according to their needs.

3. Energy Saved and Maintenance: The dryer’s cost-effectiveness in terms of energy saved and maintenance should be assessed.

4. Priority should be on advanced drying systems that use higher emissions or waste heat recovery systems.

Leading Biomass Dryer Systems at Enviropol.

Being a Biomass Dryer Manufacturer in India, Enviropol is a renowned name. Being an innovation-driven solution, the company offers state-of-the-art bagasse drying technology specific to the sugar industry of North, South, and Maharashtra. Enviropol has a vast experience of 20+ years in the Bagasse dryer installation worldwide.

Why Choose Enviropol?

1. Enviropol uses the State of Art Technology to run Biomass Dryer Systems with optimum efficiency.

2. The company provides tailor-made dryers for different sugar mills based on production scales.

3. Sustainability and Reduced Operational Costs: Emphasis on the promotion of energy efficiency within the design.

4. Enviropol is there with complete support from installation to after-sales for the clients.

Conclusion

Even though bagasse drying technology is an essential component of the sugar industry, bagasse presentation has become increasingly important with rising energy costs and environmental concerns. The investment in high-quality Bagasse dryers not only increases efficiency but also helps with sustainable operations. Enviropol, one of the leading Bagasse Dryer Manufacturers, provides Bagasse Dryer Systems that are energy efficient & innovative and cater to sugar mills in North, Maharashtra, & South India. However, partnering with industry experts is important as bagasse drying is an important part of the sugar production ecosystem that offers long-term benefits.