EPC project for Compressed Biogas (CBG) Plants

At Enviropol, we are proud to be at the forefront of India's transition to renewable energy solutions. Under the Government of India's SATAT initiative (Sustainable Alternative Towards Affordable Transportation) Oil and Gas Marketing Companies like IOCL, BPCL, HPCL, GAIL and IGL have invited Expression of interest (EoI) to procure CBG from potential entrepreneurs for further marketing, hence Compressed Biogas (CBG) is becoming a powerful alternative to conventional fuels.

By harnessing waste streams such as municipal solid waste (MSW), Spent Wash, press mud, agricultural residues, Napier Grass and cow dung, CBG offers a cleaner, more sustainable energy source while reducing our reliance on expensive fossil fuel imports. Our Engineering, Procurement, and Construction (EPC) model delivers fully integrated CBG plants that help businesses, industries, and municipalities convert waste into energy efficiently and sustainably.

With over 20 years of industry experience and 400+ successful installations across the globe, Enviropol delivers turnkey EPC solutions that ensure seamless integration with your operations, from concept to commissioning. Our expertise in biogas technology, combined with robust project management, guarantees the successful deployment of CBG plants that align with your sustainability goals and regulatory compliance needs.

What is a Compressed Biogas (CBG) Plant?

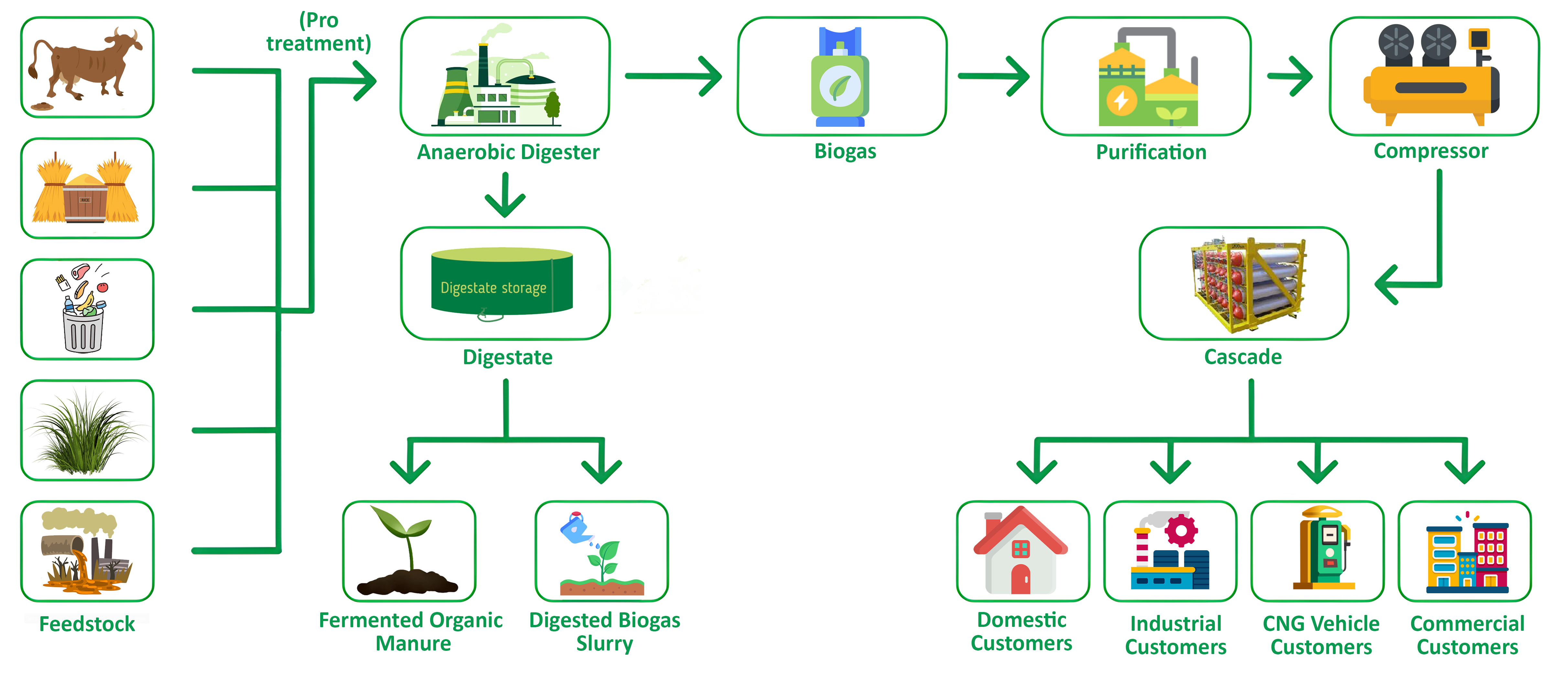

A Compressed Biogas (CBG) plant is a specialized facility that converts organic waste—such as agricultural residues, press mud, food processing by-products, and municipal solid waste—into compressed biogas, a clean, renewable gas fuel. The process involves anaerobic digestion, where organic matter is broken down in the absence of oxygen, producing biogas rich in methane CH4. The biogas is then purified to remove impurities like carbon dioxide and hydrogen sulphide, and compressed for use in energy generation, transportation fuel, or industrial applications.

Key Benefits of CBG:

- Reduces imports of natural gas, helping in energy security.

- Cleaner and greener than fossil fuels, reducing carbon emissions.

- By-product: Organic manure (solid and liquid) enhances soil health.

- Financially viable under government-backed buy-back schemes.

Enviropol Comprehensive EPC Model for CBG Projects

Enviropol EPC (Engineering, Procurement, and Construction) model offer end-to-end solutions for CBG projects, ensuring cost-effective execution and timely delivery of plants that are designed for sustainability and operational efficiency. Our services include:

- Engineering Design & Feasibility Studies

- Detailed feasibility analysis for CBG projects based on feedstock availability and expected output & ROI.

- Tailor-made designs using advanced biogas generation technology like CSTR and Plug Flow digesters.

- Feedstock Management & Pre-Treatment Technologies

- Handling and storage solutions for feedstocks like MSW, press mud, Spent Wash, rice straw, chicken litter, cow dung, and Agro waste.

- Use of advanced technologies for size reduction, moisture control, and feedstock preservation to maximize gas yield.

- Innovative pre-treatment systems for difficult feedstocks such as lignin-rich rice straw and high-moisture press mud.

- Anaerobic Digestion & Biogas Production

- State-of-the-art anaerobic digestion systems including continuous stirred-tank reactors (CSTR) and plug flow digesters for efficient biogas production.

- Optimization of fermentation processes using controlled aerobic and anaerobic microbial cultures.

- Integrated solid-liquid separation systems for post-digestion processing.

- Biogas Purification & CBG Conversion

- Advanced biogas purification technologies including Hydrogen Sulphide (H2S) removal, Carbon Dioxide (CO2) removal, and gas drying.

- Selection of appropriate purification systems such as PSA (Pressure Swing Adsorption), membrane separation, and amine-based scrubbers based on project needs.

- Compression and bottling solutions for Bio-CNG or direct grid injection for large-scale distribution.

- Post-Processing: Organic Manure (Solid and Liquid)

- Production of high-quality fermented organic manure (FOM) (Fertilizer Control Order certified) that enhances agricultural productivity.

How CBG Plants Contribute to a Greener Future

CBG has calorific value and other properties similar to CNG and hence can be utilized as green renewable automotive fuel. Thus, it can replace CNG in automotive, industrial and commercial areas. Ministry of Road Transport and Highways, Government of India had permitted usage of bio-compressed natural gas (bio- CNG) for motor vehicles as an alternate composition of the compressed natural gas (CNG).

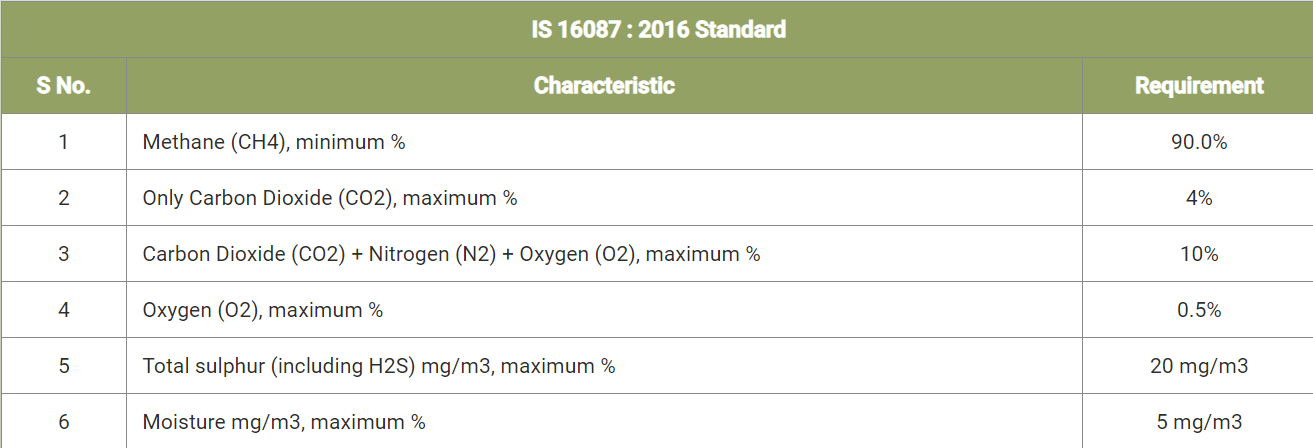

Compressed Biogas (CBG) produced from the CBG plant will be retailed through the CBG dispensing unit set-up by the Oil Marketing Companies within the radius of 25 kms. CBG supplied under SATAT scheme shall meet IS 16087:2016 specifications of BIS as follows:

Why Choose Enviropol for CBG Projects?

- Proven Experience: Over 20+ years of expertise in environmental engineering and 400+ installations globally.

- Technological Leadership: Access to the latest biogas purification, digestion, and compression technologies.

- Sustainability Focus: Commitment to delivering projects that promote clean energy, reduce carbon emissions, and minimize environmental impact.

- Government Backing: Leverage the SATAT scheme, which includes long-term buy-back agreements with oil marketing companies (OMCs)

- Financial Support: We guide clients in accessing government incentives, bank lending, and financial structuring for long-term profitability.

Government Initiatives Supporting CBG in India

The Government of India has rolled out numerous measures to support the growth of CBG under the SATAT initiative:

- Buy-back agreements with oil marketing companies (OMCs) like INDIAN OIL CORPORATION LIMITED (Indian Oil), BHARAT PETROLEUM CORPORATION LIMITED (BPCL), HINDUSTAN PETROLEUM CORPORATION LIMITED (HPCL) for the long-term purchase of CBG at pre-determined rates.

- Recognition of fermented organic manure (FOM) under the Fertilizer Control Order (FCO) for easier marketing of by-products.

- Mandatory lending directives to banks for financing CBG projects.

- Classification of CBG plants under the CPCB white category, easing environmental clearance processes.

These initiatives are designed to encourage private-sector investment in waste-to-energy projects and reduce India's dependency on imported natural gas.

How Different Industries Can Leverage CBG for Energy and Sustainability

- Sugar: Utilize press mud and Biomass to produce CBG, reducing energy costs and improving soil health with organic manure.

- Dairy and Poultry: Convert cow dung and chicken litter into CBG to power operations and generate high-quality fertilizer.

- Municipalities: Reduce landfill and urban waste by converting MSW into biogas, powering local transportation fleets with CBG.

- Food Processing: Turn organic waste into biogas to lower energy consumption and boost sustainability efforts.

- Textile and Paper: Utilize agro residues to power manufacturing processes with clean, renewable energy.

- Commercial Kitchens: Cut waste and energy costs by producing CBG from food scraps.

Partner with Enviropol for Your CBG Plant Needs

Enviropol is committed to providing top-tier EPC solutions for CBG plants, from design and procurement to installation and ongoing support. As part of India’s biofuel mission and the government’s push for renewable energy, Enviropol is taking proactive steps to accelerate the adoption of Compressed Biogas (CBG) technology across industries. Our goal is to contribute to India’s target of installing 5,000 CBG plants, making this renewable energy source accessible for industries of all sizes. Our expert team ensures that every CBG project is executed with precision, delivering long-term sustainability, operational efficiency, and cost savings. Partner with us to achieve your waste-to-energy goals and help build a cleaner, greener future.

Frequently Asked Questions

What feedstocks are best suited for CBG production?

CBG can be produced from a variety of biomass sources such as Spent Wash, press mud, cow dung, agricultural waste, municipal solid waste (MSW) & Napier Grass. At Enviropol, we design systems based on the specific availability of feedstock in your region.

What are the benefits of CBG over traditional fuels?

CBG is a renewable and environmentally friendly alternative to compressed natural gas (CNG). It reduces carbon emissions, contributes to energy security, and generates valuable by-products such as organic manure.

How Enviropol can help?

Our EPC model includes everything from engineering, design, procurement of technology and materials, and construction of the plant, to ensuring the plant operates efficiently and meets all environmental and regulatory standards.