EPC project for Biomass Pelletizing Plant

Transforming Agro Waste into High-Energy Biomass Pellets for Sustainable Energy The demand for renewable energy and carbon-neutral fuel sources is growing rapidly, with industries looking for alternatives to coal and fossil fuels. Biomass pellets have emerged as a high-efficiency, cost-effective, and environmentally sustainable fuel source.

At Enviropol, we specialize in turnkey EPC solutions for Biomass Pelletizing Plants, enabling industries to convert agricultural waste, horticulture waste, forestry residues, fermented organic manure (FOM) and industrial biomass into high-quality pellets that serve as an alternative to fossil fuels.

With over 20 years of experience and 500+ installations globally, Enviropol delivers cutting-edge biomass pelletizing technology designed for maximum efficiency, sustainability, and compliance with environmental norms using indigenous flash drying technology for moisture reduction. Enviropol delivers turnkey EPC solutions that ensure seamless integration with your operations, from concept to commissioning

What is a Biomass Pelletizing Plant?

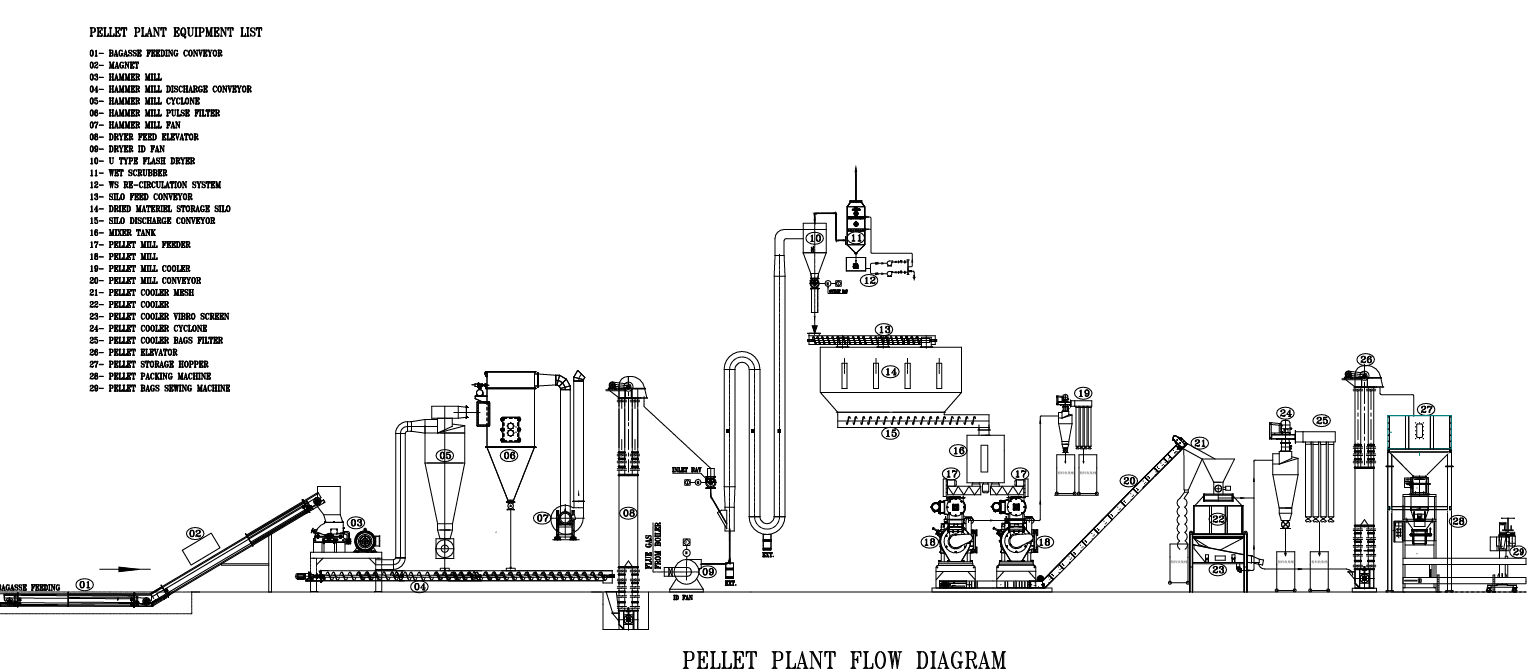

A Biomass Pelletizing Plant is a facility that converts agricultural residues, wood waste, sawdust, press mud, paddy straw, rice straw, RDF, plastic waste, bagasse, and other organic biomass into compressed biomass pellets through a specialized drying, grinding, and pelletizing process. These pellets are widely used in power plants, industrial boilers, and heating systems as a renewable alternative to coal and fossil fuels.

Key Benefits of Biomass Pellets

- High Calorific Value – Efficient alternative to coal and fossil fuels.

- Carbon Neutral – Reduces greenhouse gas emissions and supports sustainability goals.

- Lower Operating Costs – Biomass pellets are cost-effective compared to traditional fuels.

- Minimal Ash Content – Reduces maintenance costs in boilers and furnaces.

- Government Incentives – Eligible for subsidies under various renewable energy policies.

EPC Model for Biomass Pelletizing Plants

Enviropol offers end-to-end EPC (Engineering, Procurement & Construction) services, ensuring seamless execution of biomass pellet plants from concept to commissioning. Our services include:

- Plant Design

- Customized plant design based on production capacity and raw material type.

- Selection of pellet mill technology to maximize output efficiency.

- Biomass Handling & Pre-Treatment

- Raw material sizing (chipping, hammer milling, size reduction)

- Use of indigenous Flash Dryer to reduce moisture in biomass using Boiler Flue gas / SCAPH / Electricity.

- Automated feeding systems for efficient material handling.

- Pelletizing Process & Equipment

- High-pressure compression technology to form durable biomass pellets with multiple sizes to choose from.

- Horizontal die and vertical die pellet mills for different production scales.

- Advanced cooling and screening systems for uniform pellet density.

- Packaging & Storage Solutions

- Automatic bagging systems for bulk or retail distribution.

- Storage infrastructure to maintain pellet quality and moisture control.

How Biomass Pelletizing Plants Contribute to a Greener Future and Decarbonization

In an era of rapid climate change and stringent environmental regulations, industries worldwide are shifting towards sustainable energy solutions. Biomass pelletizing plants are at the forefront of this green transition, playing a vital role in decarbonization and reducing carbon footprints.

- Switching from coal and other fossil fuels to biomass pellets significantly cuts greenhouse gas emissions. Studies have shown that biomass energy can reduce CO₂ emissions by up to 80% compared to coal.

- Biomass pelletizing plants utilize agricultural residues, forestry waste, and industrial biomass, converting them into valuable fuel instead of letting them decay and emit methane. This sustainable approach to waste management not only reduces pollution but also promotes a circular economy.

- Biomass pellets offer a high calorific value and efficient combustion, making them a viable alternative to fossil fuels. Their use in industrial boilers and heating systems ensures consistent energy output with lower operational costs.

- Governments worldwide encourage the adoption of biomass energy through subsidies, incentives, and carbon credit programs. Industries that use biomass pelletizing plants can benefit from carbon offsets and compliance with emission norms, enhancing their corporate social responsibility (CSR).

- With the volatility of fossil fuel prices and growing demand for renewable energy, biomass pellets offer a stable and sustainable fuel source. Industries can minimize dependency on coal and oil, promoting long-term energy security.

Industries Benefiting from Biomass Pelletizing Plants

- Power Plants & Industrial Boilers

- Cement & Steel Industry

- Food Processing & Textile Industry

- Residential & Commercial Heating

- Waste-to-Energy & Biomass Gasification Plants

Why Choose Enviropol for Biomass Pelletizing Plants?

- 20+ Years of Industry Expertise – Leading the way in biomass energy solutions.

- Turnkey EPC Execution – Comprehensive solutions from feasibility to commissioning.

- Indigenous Flash Drying Technology – High-efficiency pellet mills, drying systems, and automation.

- Sustainability & Compliance – Ensuring compliance with pollution control norms.

- Proven Track Record – Successfully deployed renewable energy projects across industries.

Frequently Asked Questions

What raw materials can be used for biomass pelletization?

Biomass pellets can be made from paddy straw, rice straw, sawdust, wood chips, bagasse, press mud, fermented organic manure, plastic waste, agro-residues, horticulture waste etc.

How does biomass pelletization benefit industries?

Industries can reduce fuel costs, reduce transportation cost, cut emissions, and comply with green energy mandates by switching to biomass pellets.

What is the calorific value of biomass pellets?

Biomass pellets have a calorific value between 3,800-4,500 kcal/kg, making them a high-energy alternative to fossil fuels.

How much does it cost to set up a biomass pellet plant?

Costs vary based on plant capacity, raw material availability, and automation level. Enviropol provides cost-effective EPC solutions tailored to your needs.

Why should industries invest in biomass pellet plants now?

With rising coal prices, focus on decarbonization, and stricter environmental regulations, biomass pelletization offers a cost-effective, sustainable alternative.